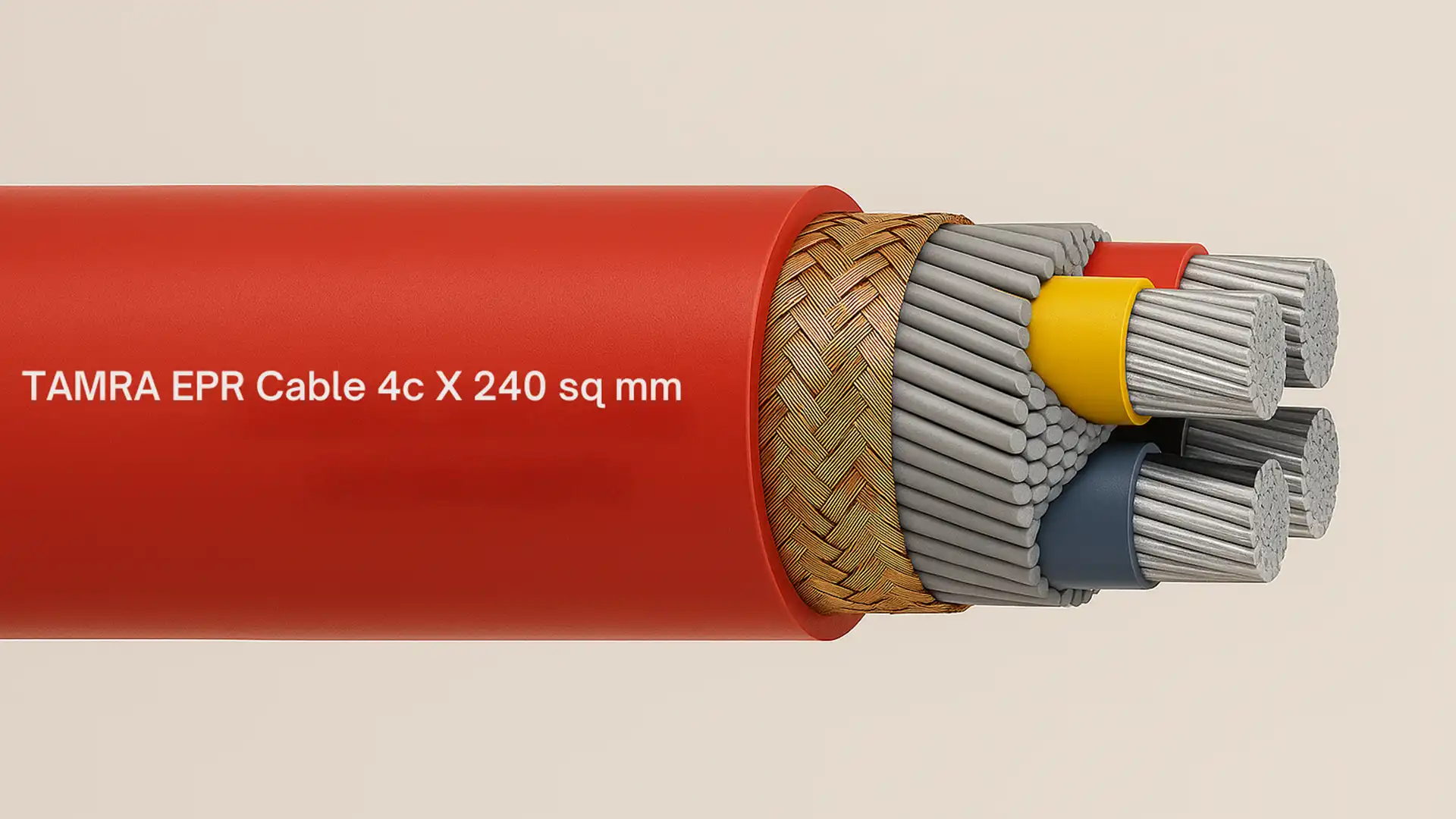

At Tamra Wires & Cables, we manufacture EPR (Ethylene Propylene Rubber) insulated cables engineered for demanding industrial, marine, mining, and offshore applications. Unlike conventional PVC or XLPE cables, EPR cables offer exceptional flexibility, high thermal stability, and superior electrical insulation even under wet or chemically aggressive environments.

Our EPR cables are designed to operate continuously at 90°C, withstand short circuits up to 250°C, and perform reliably in temperatures as low as -40°C. Built with robust elastomeric insulation and sheathing compounds, they provide outstanding resistance to heat, oil, chemicals, ozone, and mechanical stress, making them the preferred choice for industries where durability and safety are non-negotiable.

Backed by IRS/IEC/IS standards and tested in our NABL-approved laboratory, Tamra EPR Rubber Cables deliver consistent performance and long service life, whether in mines, steel plants, refineries, offshore rigs, shipboards, or heavy-duty mobile equipment.