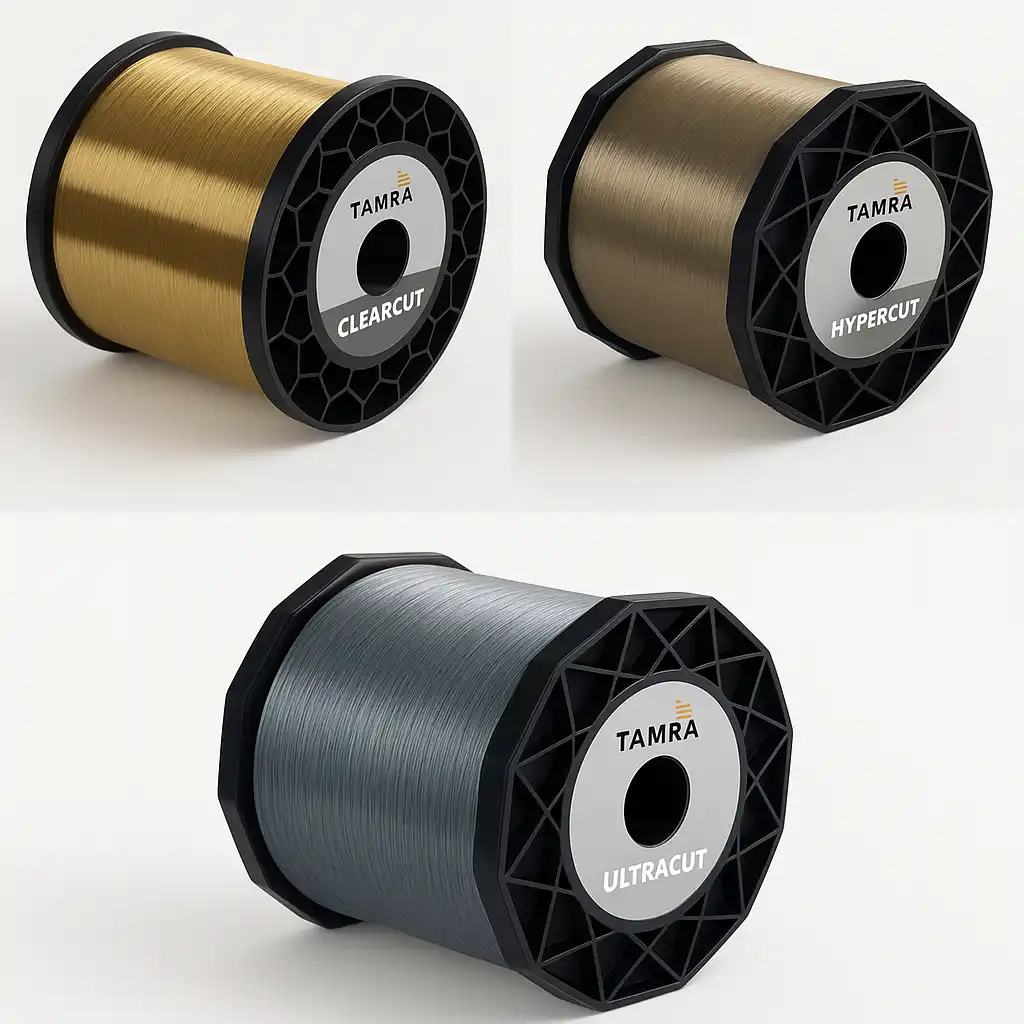

Tamra’s EDM Wire is precisely engineered for cutting metals via electric discharge machining. Produced through strict process control—from casting through drawing and continuous annealing—these wires deliver unmatched tensile strength, diameter precision, and straightness.